The last week of school is: Rocket Week!! This year I decided to take part in the fun. I’ve wanted to shoot off a big model rocket for a while, and when I was buying model rocket motors in Anchorage back in August I simply couldn’t not pick up the largest motor they had that didn’t require a license (an Aerotech G80-10, for the interested). When I ordered rocket kits for the kiddos, I also ordered a big rocket for the big motor.

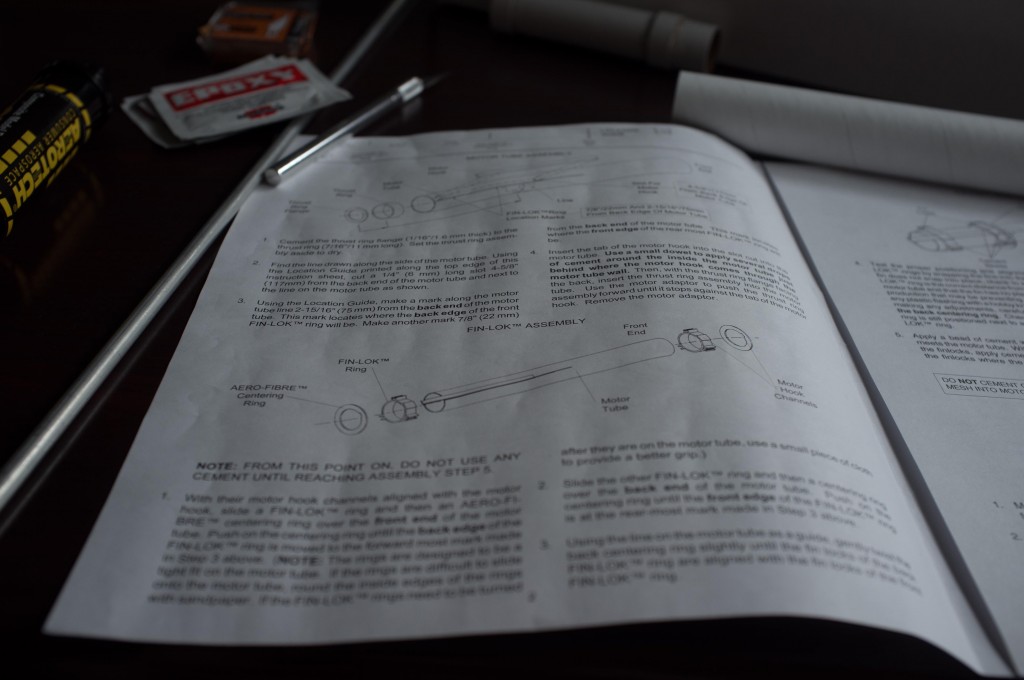

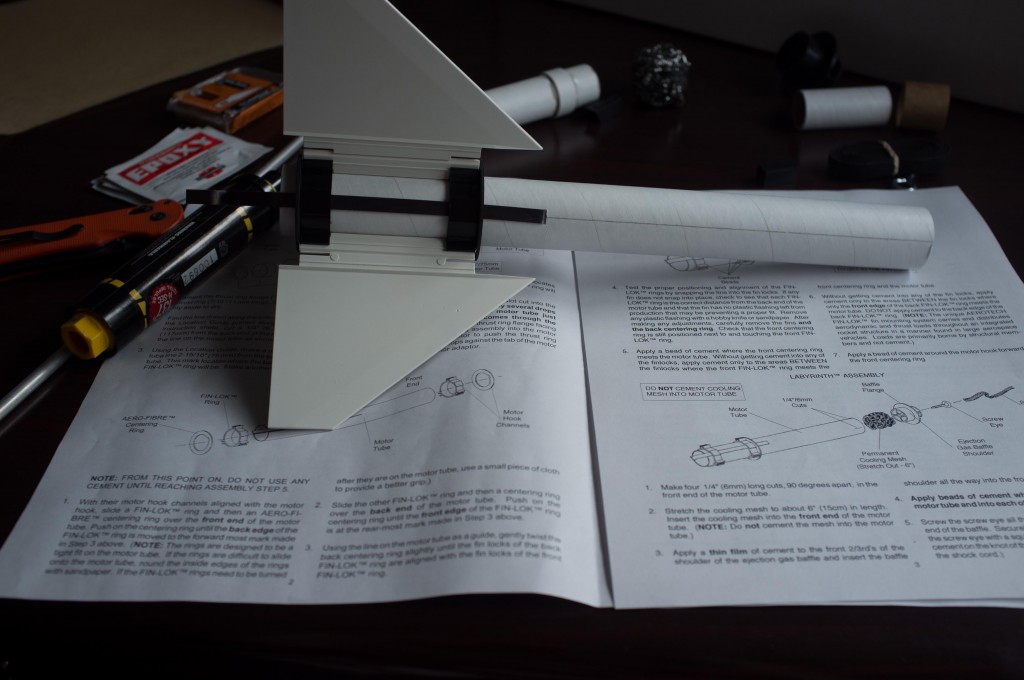

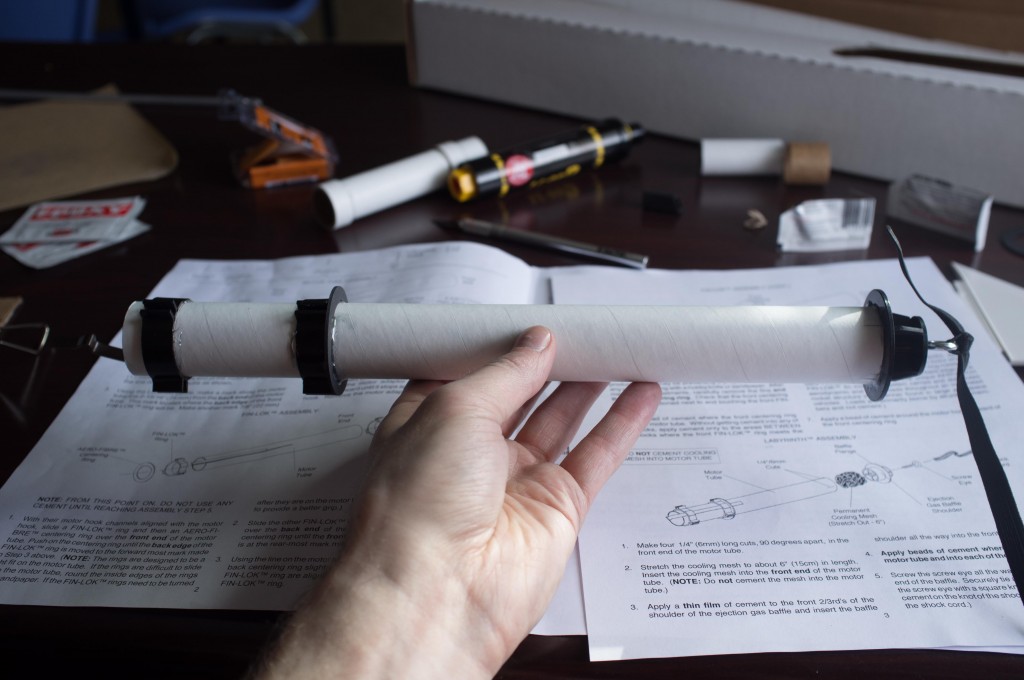

Since next week is the last week, today was building time! The motor mount is all done (approximately half the work). It was very interesting and kinda fun to put together: unlike the small rockets I’ve made before, this model’s design manifests significant thought towards distributing the motor’s impulse effectively to the body through surface to surface joints and not through cement/glue/epoxy joints. Which is to say it made me feel a little bit like a rocket scientist as I worked.

Also, according to a youtube video, this sucker should get to 2000 to 3000 feet, traveling at 600+ mph. Yeah! Awesome!

Er..also..yeah..that does make me a little nervous. Did I mention the launch-button-controller thing has all of twenty feet of wire between the switch and the alligator clips? I’m seriously considering building a plywood box with a narrow-slit-window from which to control/launch/video the launch.

Movies, take backup movies! WhooHoo!